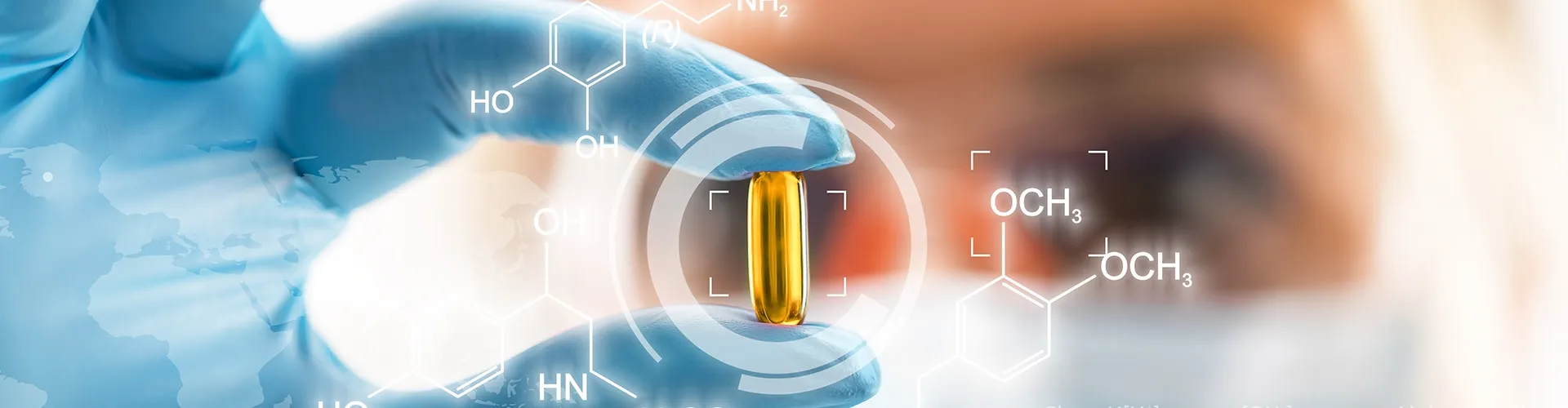

Oil Analysis

Machine health, safety, and efficiency depend on appropriate lubrication. Thorough and proper lubrication can protect from overheating, inefficiency, and wear and tear. Therefore, lubricants must be checked often to ensure that mechanical components are adequately lubricated, and Oil Analysis can help.

Oil Analysis investigates the quality of the lubricant used; it could also highlight any damage to mechanical components. It is essential to condition-based maintenance measures.

Phoenix recommends regular oil analysis for our clients and provides oil analysis services with utmost care. Our oil analysis services’ results include the following.

Lubricant condition

A lubricant’s condition can be ascertained from oil analysis, allowing us to establish if a lubricant meets the needs of a specific model or type of machinery. Information such as the age, quality, grade or texture of a lubricant enables us to determine if it is being rightly employed or not.

Impurities present in the lubricant

Contaminants are a significant issue of concern in lubricants. They are unavoidable even when due care is taken to avoid them. Anything from dust to debris arising from the machine itself to moisture and sludge can affect a lubricant’s ability to perform its purpose.

Oil analysis can therefore help ascertain if a lubricant has been contaminated and whether the number of impurities will cause problems along the way.

Mechanical status of the equipment

Mechanical components can wear off due to constant use, especially components that constantly contact other components, such as gears. Lubricants slow down this process exponentially.

However, still, wear and tear is only natural. Thus, oil analysis can determine the state of repair a machine is in, highlighting where repairs might be required by analysing the debris found in the fluids and helping you save expensive equipment in time.

Why Phoenix?

Phoenix understands that only a high-end lubricant can bear great results. The saying “a stitch in time saves nine” is valid for oil analysis. Regularly timed oil analysis can save a lot of time, effort, and money as it enables you to take the necessary measures to extend your equipment’s service life.